Background

The Terra-Gen Operating Company in conjunction with the Department of Energy required the design and installation of a custom heat exchange structure at the Dixie Valley Geothermal Power Plant near Fallon, Nevada. Signature Structures worked with Thermal Solutions to design, fabricate and install a custom structure to support the heat exchange units and stand up to the harsh desert environment.

Solution

The Signature Team provided a structural evaluation of the steel support structure for the heat exchanger using Computer-aided structural frame analysis to determine different load combinations to identify critical aspects of the design. After a thorough design review, the Dixie Valley Project presented a unique challenge in specifying what membrane could be used. The unique application and environmental conditions required that the Signature Teamwork with Seaman Corporation to design a hybrid membrane solution to meet and exceed all design requirements and hold a warranty that would satisfy Signature Structures and the customer.

Details

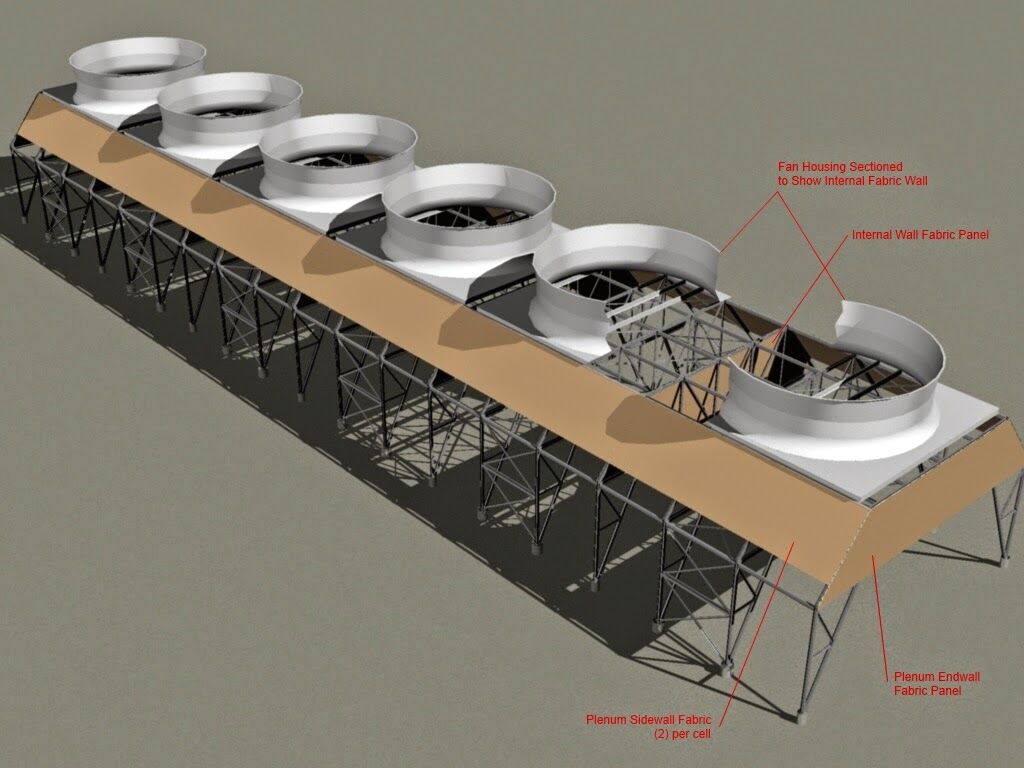

Measuring 60’ wide x 262’ long x 33’ high, The Heat Exchange Structure consists of six cells, each comprised of one fan unit and three cooling bundles. The structural steel frame is made of ASTM A572 Grade 50 web trusses separated by I-Beams to provide lateral stability to the trusses. The heat exchange plenum section is clad in non-prestressed fabric skin connected to the frames by edge ropes and flat bars. Since the fabric is not attached to the purlins, it transmits the effects of suction pressures directly to the supporting frames. Having survived in the worlds harshest conditions, the hybrid membrane combining high performance 8028 architectural fabric with the XR-5 geomembrane was selected to meet the project requirements.

Check out our Industrial Structure Projects or contact one of our experts for assistance with your next environmental/DOE structure application.